Sustainability in the building sector

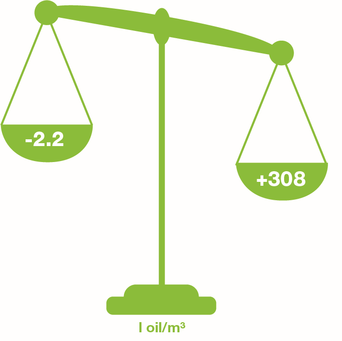

Comparing the energy input for manufacturing 1kg of ArmaFlex with the energy saving achieved during its in-use phase shows an outstanding energy balance.

The energy input needed to manufacture ArmaFlex is paid off after just 50 days.

If the CO2 emissions are considered, a similar picture emerges: during its use ArmaFlex prevents the emission of 150 times more greenhouse gases than are released during its production – with a service life of 20 years (cold applications) and 30 years (heating applications), based on conservative assumptions.

This can also be expressed in terms of cost benefits or cost savings over the entire service life of ArmaFlex insulation materials. Amortisation calculations for typical applications have shown that the cost of the insulation material used has been recovered after just one to two years.

Since an LCA can only provide very specific information on an individual manufacturer’s products, the results cannot be transferred to the products of other FEF manufacturers. Deviations in the raw materials used or the production process as well as the very different manufacturing footprints of the providers have a significant impact on the data. The system of the LCA and EPDs inevitably requires information to be restricted to specific products and/or the manufacturer.