PIONEERING AND INNOVATIVE TECHNOLOGY

Armacell is a pioneer in the field of polyethylene terephthalate (PET) technology and initiated the breakthrough of PET-based foam cores in the composite industry (2005). Ever since, Armacell has invested significantly in the research and development of this state-of-the-art technology, and developed a process technology that enables the production of PET foam products using post-consumer PET beverage bottles.

In 2010, we launched the world’s first structural foam core based on 100% recycled PET (rPET) plastic. Today, our entire PET foam product portfolio is based on this pioneering process technology. This patented rPET technology allows us to convert waste material into a high-quality resource and feed it back into the production cycle.

"There is a sustainable alternative to single-use plastics, and Armacell is playing its part in working towards a circular model. In reusing plastic bottles, Armacell is making a difference around the world." (Patrick Mathieu, President & CEO of the Armacell Group)

CLOSING THE LOOP

The circular economy involves switching from a linear 'make-take-dispose' economy to a circular one based on 'reduce, reuse and recycle'. An economy in which waste and pollution are designed out, products and materials are kept in use longer, and natural systems are regenerated. The plastics circular economy is a model for a closed system that promotes the reuse of plastic products, generates value from waste, and avoids sending recoverable plastics to landfill.

In the post-consumer life cycle of a plastic bottle, Armacell’s patented reprocessing technology creates a virtuous eco cycle. After collection, the PET bottles are sorted and then crushed into flakes. This is followed by an in-house granulation process and, finally, extrusion foaming.

In this way, used plastic bottles are converted into long-lifetime, high-value foam core materials for composite sandwich structures, which are utilised in up to 90-metre-long wind turbine blades, high-speed train body structures, surfboards, and even on the 24-karat gilded roof of an orthodox cathedral. Since production started in 2010, we have used more than two billion recycled PET bottles in our worldwide PET foam production.

FROM BOTTLE TO A HIGH-TECH FOAM

Today, the sustainability of the individual component is becoming a relevant decision criteria in the materials selection process. The trend of designing environmentally-friendly composite structures that are light, strong and recyclable has led industrial designers, specifiers and composite manufacturers to accelerate the substitution of conventional polymeric foam materials with our ArmaPET product suite.

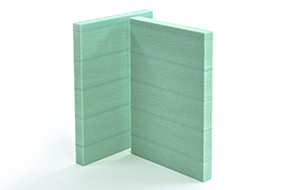

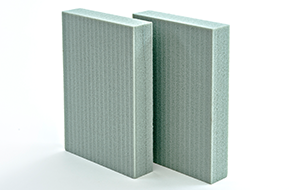

Our comprehensive offering of innovative eco-friendly PET foam product solutions includes: structural and insulating foam cores, thin flexible sheets for thermoformable micro sandwich solutions and particle foams to produce 3D foam parts.

Whether you are looking for composite materials in the wind energy sector, searching for insulating core materials for building and construction, or would like a choice of fire safety materials for railway composite applications, ArmaPET enhances innovative product solutions. No matter the market or application, ArmaPET provides a high-performance and highly environmentally friendly alternative to PVC, Balsa, SAN, PUR or honeycomb core materials and other comparable foam product.