Münster, 15 July 2014 – The risk of legionella rises in summer: during the holiday period water stagnates in the pipes, making HVAC and plumbing systems an ideal breeding ground for the hazardous bacteria. Scientists estimate that every year 15,000 to 30,000 people in Germany contract Legionnaires’ disease, a form of pneumonia transmitted by pathogens in water. Contaminated air-conditioners, swimming pools or whirlpools are well-known sources of infection. But errors made in the design and installation of sanitary systems can also lead to a dangerous rise in legionellae in drinking water. Therefore, one of the most important preventative measures is to insulate hot and cold water pipes correctly using suitable materials.

95 % of cases of Legionnaires’ disease are not recognized

Legionella are bacteria which can get into the drinking water systems of buildings through the central water supply. They are particularly likely to multiply in stagnant water at temperatures between 25 and 45 °C. The bacteria become a hazard when they are inhaled as small droplets (e.g. as aerosols when taking a shower). People who are chronically ill or bed-ridden or have a weak immune system are at particular risk of contracting Legionnaires’ disease, which may be fatal. Because the symptoms are similar to those of flu, the condition is often not diagnosed correctly. The Community-Acquired Pneumonia Competence Network (CAPNETZ) estimates that there are some 15,000 to 30,000 cases of Legionnaires’ disease in Germany every year. This would mean that 95 per cent of cases go unrecognized, although the disease must be reported.

A combination of measures to prevent microbial contamination

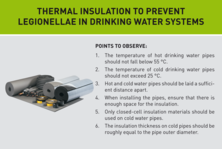

There are a number of operational, constructional and process-related measures to avoid a harmful multiplication of legionella in drinking water and, where possible, a combination of these should be implemented. Apart from ensuring that the water circulates continuously through the pipework, it is also necessary to prevent unacceptable temperature decreases in hot water pipes and increases in cold water pipes. According to the European standard DIN EN 806-2, pipes for cold drinking water should not follow the routes of space heating or hot water pipes nor should they pass through heated areas such as airing cupboards for clothing and linen. Cold water pipes should be protected against heat gain by ensuring sufficient clearance or insulating properly. Similar requirements apply for hot water pipes to protect them against heat loss.

Hot pipes must stay hot, cold pipes cold

The minimum thickness of the insulation material for pipes and fittings must meet local or national requirements. The pipes must be adequately insulated if there is an increased risk of legionella, for example because hot and cold pipes are laid in one duct or wall slot or water does not circulate regularly. Here Armacell recommends using what is known as 100 % insulation, i.e. an insulation thickness which roughly corresponds to the outer pipe diameter. On hot drinking water pipes this not only prevents legionella, but also protects the pipes against unnecessary energy losses.

Suitable insulation materials prevent condensation

Because of the risk of condensation, only closed-cell insulation materials with a high resistance to water vapour diffusion should be used on cold drinking water pipes. In practice, damage events have shown that open-cell insulation materials (no matter whether with or without a vapour barrier) do not sufficiently prevent moisture ingress as a result of diffusion. Therefore they cannot be regarded as effective protection against condensation. With such materials the resistance to water vapour diffusion is concentrated on the vapour barrier. Even if the systems are installed with the greatest care, they may not be completely tight and water ingress often cannot be avoided. This means that there is a danger of water vapour present in the air penetrating the insulation, condensing and quickly soaking the insulation material. As the material becomes damper and damper, the thermal conductivity increases, the insulation properties deteriorate and energy losses rise. Furthermore, corrosion and expensive consequential damage can occur.

Armacell insulation materials protect pipes against unacceptable temperature increases and decreases

Due to their excellent technical properties, AF/ArmaFlex, SH/ArmaFlex and Tubolit insulation materials reliably prevent the temperature of the pipes increasing or decreasing unacceptably and at the same time protect the installations against energy losses. The closed-cell material structure prevents moisture ingress and thus corrosion on the pipes. AF/ArmaFlex, SH/ArmaFlex and Tubolit fulfil the requirements of the German DIN 1988-200 and the energy-saving regulation.