ArmaFlex insulation materials very well protected against moisture absorption; Sustained high energy efficiency

Münster, 19 March 2018. – Damp insulation is as useless as a wet woollen coat in winter. It does not protect the equipment against either energy losses or corrosion. A study by the Fraunhofer Institute for Building Physics has now confirmed that ArmaFlex insulation materials are very well protected against moisture absorption. The closed-cell elastomeric insulation material also achieves a sustained increase in the energy efficiency of technical systems. However, using mineral fibre materials on refrigeration pipes means taking an incalculable risk that can lead to significant follow-up costs.

Condensation – the deadly enemy of any insulation

For technical insulation, condensation is enemy number 1: if moisture forms on the surface of pipes or water vapour penetrates the insulation material from the outside, the insulation system has failed. The insidious thing about moisture penetration and condensation is that the processes are not visible. Condensation occurs under the insulation on the surface of the pipe. It often only becomes apparent that the insulation material has failed when the material is so wet that water drips from the suspended ceiling or ice forms on the pipe.

If moisture penetrates the insulation material:

- energy losses increase,

- corrosion can occur under the insulation,

- mould can grow and

- high repair and follow-up costs are incurred.

The insulation effect declines rapidly and the material eventually loses its function. So when selecting an insulation material, the key question is how well it is protected against moisture absorption.

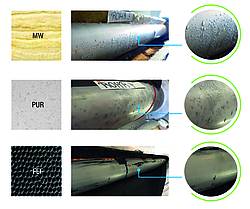

Insulation materials in an independent test

To study the moisture and condensation behaviour of various insulation materials, Armacell commissioned the Fraunhofer Institute for Building Physics (Stuttgart, Germany) to carry out a scientific test. The materials investigated were mineral fibre, PUR and FEF (flexible elastomeric foam). While the closed-cell elastomeric material has an “integrated” vapour barrier and the resistance to water vapour transmission is built up cell by cell throughout the insulation thickness, in mineral-fibre and PUR products the vapour barrier is restricted to a thin aluminium or PVC foil. In practice, it is almost impossible to apply this foil in such a way that adequate water-vapour tightness is achieved. Pipe brackets, elbows, T-pieces, valves, fittings etc. are hardly ever completely vapour tight. To simulate damage to the insulation system, which is the rule rather than the exception on the building site, two small holes (Ø 5 mm) were drilled 5 mm deep into the surface of three of the six specimens. The test conditions in the climate chamber were deliberately chosen to be moderate: the pipes were run at an operating temperature of 20 °C. The ambient temperature was defined as 35 °C and the relative humidity as 55 %. The test was conducted under these conditions for 33 days.

Condensation on the pipes

During this relatively short test period, a significant amount of moisture had already gathered under both the PUR and mineral-fibre insulation. Even in these moderate conditions, the vapour barrier could not prevent the absorption of water vapour. In contrast, no moisture had diffused into the elastomeric insulation material and the surface of the pipe was dry. While the pipe insulated with FEF showed no sign of condensation after 33 days, the mineral-fibre insulation failed right at the beginning of the test, both with and without damage.

Long-term consequences of moisture penetration

To investigate the long-term effects of moisture absorption, the Fraunhofer Institute carried out calculations on the basis of these results and simulated how the insulation materials behave over an assumed period of ten years. While the thermal conductivity (λ) of the FEF has only risen by around 15 % after ten years, the λ-value of the mineral wool is 77 % higher and that of the PUR insulation 150 %. The thermal conductivity increases with every vol.-% of moisture content and the insulation effect deteriorates rapidly. The consequences are not only steadily rising energy losses over the service life, but also a fall in the surface temperature. If this drops below the dew-point temperature, condensation occurs and the risk of corrosion rises.

Elastomeric insulation protects against condensation

To prevent condensation on the pipe surface and an increase in the thermal conductivity over the service life, it is essential that the insulation material is protected against moisture absorption. The thermal conductivity stated must be understood as being the initial thermal conductivity or “dry λ-value”. Only in combination with the resistance to water vapour transmission may it decide which material is selected. In other words: an insulation material with an excellent “dry λ-value” but low resistance to water vapour transmission is a bad choice.

If the insulation material is completely soaked, the increase in energy consumption is often the least of the problems. Mould, structural damage, e.g. to suspended ceilings, or disruption to industrial processes due to maintenance work and down-time can result in huge costs.

Don’t take an incalculable risk

By using open-cell insulation materials in cold applications specifiers and installers are taking an incalculable risk, which can cost them dearly. Manufacturers of mineral-fibre products currently promote their insulation materials as being suitable for use in cold applications. Even if these systems are explicitly marketed as cold insulation materials, they are open-cell mineral-fibre products with an aluminium foil. The manufacturer’s 15-year guarantee does not alter the fact that in the event of a complaint the user is required to prove that the product was installed correctly.

In some European countries, the use of mineral wool on refrigeration pipes is severely restricted. In Germany, DIN 4140 stipulates that it is only allowed if a double jacket is installed. In Belgium, according to Typebestek/105, mineral wool may only be used on pipes with a minimum temperature of 13 °C.

Cold insulation materials should have a closed-cell structure, high resistance to water-vapour transmission and low thermal conductivity. Only then is it possible to ensure that diffusion processes are kept to a minimum permanently.

Tip: The risk of moisture absorption in insulating materials is also the subject of a current information campaign by Armacell. The company uses videos, infographics, brochures and a special feature on its website to provide information about the consequences of damp insulation. See www.armacell.eu for more details.