By Dipl. Ing. Michaela Störkmann, Armacell Manager Technical Department Europe

Münster, 15 July 2013 – In a fire, low smoke density can be of vital importance in allowing passengers and staff in railway vehicles to escape and be rescued quickly and safely. For this reason, the new European standard EN 45545-2 defines tighter requirements for the fire behaviour of materials and components. In future, only technical insulation materials with hazard level HL2 may be used in many trains. With ArmaFlex Rail SD Armacell provides the first highly flexible, closed-cell insulation material for air-conditioning and refrigeration equipment that meets the stricter fire protection requirements in rail vehicle construction.

Plastics such as modern fibre-reinforced composites are increasingly used instead of traditional steel or aluminium constructions in rail vehicles. Not only are they considerably lighter and allow an energy-efficient operation of the trains, they are also corrosion-free and can be cast into complex shapes easily. Synthetic rubber based insulation materials (FEFs: Flexible Elastomeric Foams) have been proving their worth for insulating air-conditioning and ventilation installations for decades. Climate control is of great importance in modern rail vehicle technology: due to high outdoor temperatures even in central and northern Europe and the greater comfort now expected by passengers, state-of-the-art air-conditioning technology is essential in rail vehicle construction today. Depending on where the trains are operated, air-conditioning the passenger compartments can account for up to 30 per cent of the total energy consumption. Yet the energy required can be greatly reduced through intelligent climate control systems and efficient thermal insulation of the vehicles and installations. Significant energy and cost savings can be achieved by using suitable technical insulation materials.

Technical insulation materials have to meet many different requirements

Today, technical insulation materials have to meet many requirements. They reduce energy losses and/or the transmission of structure-borne noise from the installations and prevent condensation on the surface of cold pipes and ducts, which could result in moisture penetrating the insulation material and adjoining components. In addition to these functional requirements, there are safety requirements, which also play a decisive role when selecting a product. For example, it must be environmentally compatible, represent no health risk and have certified fire behaviour. Synthetic rubber based insulation materials have very good technical properties: they are closed-cell, have a high resistance to water-vapour transmission and a low thermal conductivity, thus providing installations with long-term protection against energy losses and condensation. Unlike conventional insulation materials, which have to be protected against moisture penetration with a separate vapour barrier, in FEF products the resistance to water vapour transmission is built up throughout the entire insulation thickness. This provides much more security than the diffusion barriers of open-cell insulation materials, which usually consist of aluminium foils and can easily be damaged during installation or maintenance work and then permit water ingress. Elastomeric insulation materials on the other hand ensure reliable long-term protection against condensation processes. Moreover, insulation materials with Microban® technology are available, which provide additional protection against harmful microbes such as bacteria and mould.

When assessing and selecting technical insulation materials, installation aspects are as important as the physical-technical values. Depending on the complexity of the objects to be insulated, different requirements are made of the insulation material. The effort needed to install the insulation systems and the reliability of the installation are particularly significant. Even under difficult circumstances, it must be possible to carry out the installation in such a way that there are no weak points in the entire construction. Here elastomeric insulation materials offer enormous advantages for railway vehicle construction: they are lightweight and highly flexible – even extreme radii present no problems for the insulation materials. Elastomeric insulation sheets can be supplied in virtually every required insulation thickness. The homogenous, three-dimensionally cross-linked structure of the elastomeric material means that the sheets can be cut cleanly. There are no hazardous emissions due to dust or fibrous particles that could be breathed in. The high flexibility of the material allows it to be fitted easily even on complex installations. If self-adhesive sheets are used, the application times can be reduced further.

Strict fire protection requirements for rail vehicles

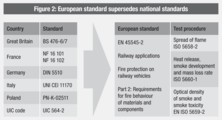

Rail vehicles have to meet strict fire protection requirements. National standards currently still apply in Europe and in in some cases they differ greatly from each other, as far as both the testing procedure and the evaluation of the test results are concerned. The phase in which the fire breaks out is decisive for assessing the fire behaviour of synthetic insulation materials. A seminal description of the fire behaviour of plastics is given by Troitzsch [1].

The characteristic parameters for fire behaviour are:

- Ignition

- Spread of flame

- Heat release (or temperature rise)

- Smoke development

- Smoke toxicity

To assess and evaluate the fire behaviour, standardized fire tests have been developed, which are intended to reproduce the situation of the fire risk. As the escape opportunities are limited in rail vehicles, the composition of the fire gases is also considered to be relevant for safety.

European fire classification in rail vehicle construction

Up to now there have been numerous different national regulations for assessing the fire behaviour of materials and components used in rail vehicle construction in Europe. However, with the adoption of EN 45545-2 (Rail applications – Fire protection of rail vehicles, Part 2: Requirements for the fire behaviour of materials and components), which comes into force in 2013, binding harmonized testing procedures and a European fire classification now apply for rail vehicle construction in Europe.

In 1997, the European Commission together with the industry initiated the FireStarr project, in order to ensure the interoperability of the Trans European high-speed rail system. This project was intended to support the work of the European standardization committees CEN/TC256/WG1 and CENELEC/TC9X/WG3 and led to the Technical Specification DIN CEN/TS 45545 (2009-07) – the forerunner to the standard that has now been passed. As different test procedures and approval crite-ria had applied in the European countries until then, new test methods had to be found.

After many years of groundwork, EN 45545 Part 2 was officially published in June 2013 and the national standards have to be withdrawn by March 2016 at the latest. In the transition phase, the national standards, such as DIN 5510, BS 6853, etc., continue to apply alongside the new European directive.

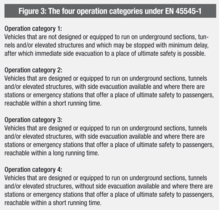

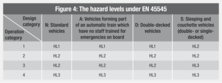

The overriding aim of EN 45545 is to minimize the risk of fires breaking out and spreading in rail vehi-cles and to protect passengers and train staff from the consequences of fires, in order to achieve the highest possible level of safety in trains. To this end the FireStarr project first defined four different types of rail vehicle (design categories A, D, S and N, see Figure 4) and four operating categories (1 to 4, see Figure 3) and examined the fire behaviour of the various materials and components.

The operating and design categories represent the requirements of the current operating circum-stances for public rail traffic in Europe. While the design categories reflect the various types of vehicle (standard, double-decked or sleeping vehicles, for example), the conditions in which the trains run is defined in the operating categories. Obviously, vehicles that were built for use in tunnels and that must travel longer before they reach stations or emergency points represent a greater safety risk in the event of a fire than trains that are not suitable for underground sections or elevated structures.

With Part 2 of EN 45545 the effects of a fire, in the form of heat, smoke and toxic gases, on passen-gers and staff should be minimized through the specification of the materials used in rail vehicle con-struction. The fire behaviour of materials and components depends not only on the specific properties of these materials, but also on where they are used within the construction, the shape and arrangement of the material, the surface directly exposed, the relative mass and the density of the material. On this basis the products listed were classified and assigned to sub-groups according to:

- their general location (interior or exterior)

- their specific use (furniture, electro technical equipment, mechanical equipment)

Depending on where they are located and their fire risk, the materials were assigned to the categories R1 to R26 (R = requirement set). The operating and design categories according to DIN EN 45545-1 are used to determine the hazard level (HL) that the requirements of the classification system are based on. There are three hazard levels in all (HL1 to HL3). HL3 is the highest level and thus makes the highest demands of the materials.

Requirements for the fire behaviour of combustible technical insulation materials

In EN 45545-2, technical insulation materials are listed under IN1 (interior components – horizontal downward facing surface; horizontal upward facing; surfaces within cavities, wall – vertical surfaces) and therefore requirement set 1 applies.

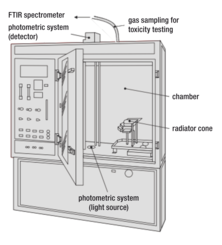

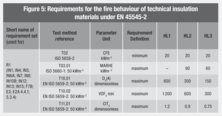

The requirement sets call for various fire tests and the test results are assigned to the hazard levels HL1 to HL3. As R1 materials, technical insulation materials are tested under ISO 5658-2 (spread of flame), ISO 5660-1 (heat release, smoke development and mass loss rate) and EN ISO 5659-2 (optical smoke density and toxicity).

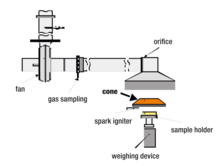

In the test under ISO 5658-2, the lateral spread of flame is determined on the vertically oriented specimen using a radiant panel and an additional gas burner flame as ignition sources.

EN 45545-2 makes specific requirements for the smoke density and toxicity of almost all combustible materials and components. The requirements depend on the hazard level of the vehicle. Illustration 6 shows the test set-up under EN ISO 5659-2.

Figure 5 shows the test results for combustible technical insulation materials required for the various hazard levels.

Elastomeric insulation materials with low smoke development

Like all organic products, flexible elastomeric insulation materials are combustible. In order to ensure that the insulation material is optimally protected against fire, various flame retardants are added. Flame retardants are additives that reduce the ignitability and burning rate through physical and/or chemical action, but do not prevent the materials themselves being combustible. Brominated flame retardants inhibit combustion very effectively, but due to their mode of action and their effect they lead to high smoke development especially in the gas phase and do not achieve the required hazard levels.

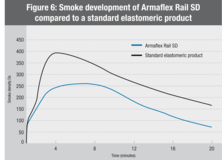

By taking a completely new approach Armacell has now been able to resolve this conflict of objectives. Due to the development of completely new, intrinsically flame-resistant polymers and using ablative protective additives it is no longer necessary to add any brominated flame retardants. The completely new foam ‘ArmaFlex Rail SD’ combines for the first time extremely high flame resistance with minimal smoke development. The blue elastomeric foam is the first flexible insulation material to achieve hazard level HL2. In comparison to a standard elastomeric product, ArmaFlex Rail SD displays much lower smoke development.

Summary

The standards organizations have recognized that smoke represents a much higher potential risk than the fire itself. This is reflected in the new fire classification for European rail vehicle construction. The requirements for smoke development and toxicity are likely to be further tightened when EN 45545-2 is revised. In November 2012, after around three and a half years of work, the EU research project TRANSFEU (Transport fire safety engineering in the European Union) completed its task and presented its final report. The project was coordinated by the French Laboratoire National de Métrolo-gie et d'Essais (LNE) and carried out by a consortium of fire testing institutes, research centres, rail-way operators, standards organizations and other institutions. Its emphasis lay on the toxicity of fire gases on trains and ships. The concept that TRANSFEU developed for testing and assessing the smoke toxicity of the various materials is likely to be included in the revised version of EN 45545-2.

Armacell is continuously enhancing its insulation materials for rail vehicle construction in order to be able to meet the requirements of the future, too.

References

[1] Jürgen Troitzsch: Plastics Flammability Handbook - Principles, Regulations, Testing and Approval, 3rd Edition, Carl Hanser Verlag München 2004.

[2] EN 45545-1:2013: Railway applications – Fire protection of railway vehicles – Part 1: General.

[3] EN 45545-2:2013: Rail applications – Fire protection on railway vehicles – Part 2: Requirements for fire behaviour of materials and components.

[4] ISO 5658-2:2006-09: Reaction to fire tests - Spread of flame - Part 2: Lateral spread on building products in vertical configuration.

[5] ISO 5660-1:2002-12: Reaction-to-fire tests - Heat release, smoke production and mass loss rate - Part 1: Heat release rate (cone calorimeter method).

[6] EN ISO 5659-2:2013-03: Plastics – Smoke generation - Part 2: Determination of optical density by a single-chamber test (ISO 5659-2:2012).

[7] www.transfeu.eu

[8] Dipl. Ing. Michaela Störkmann: “Brandverhalten Elastomerer Dämmstoffe” (Fire behaviour of elastomeric insulation materials), In: Isoliertechnik 5/2000, pp. 48 - 55.

Abstract

In a fire, low smoke density can be of vital importance in allowing passengers and staff in railway vehicles to escape and be rescued quickly and safely. For this reason, the new European standard EN 45545-2 defines tighter requirements for the fire behaviour of materials and components. In future, only technical insulation materials with the hazard level HL2 may be used in many trains. With ArmaFlex Rail SD Armacell provides the first highly flexible, closed-cell insulation material for use in cold applications, which meets the stricter fire protection requirements in rail vehicle construction.