Münster, 12 February 2013. – Since 2010, teams of students from all over the world have been taking part in a biennial solar energy challenge. The Solar Decathlon Europe in Madrid is an interdisciplinary competition in which energy self-sufficient buildings are designed, built and then assessed by an expert jury. The contests include: Architecture, Engineering and Construction, Energy Efficiency, Electrical Energy Balance, Comfort Conditions, Functioning of the house, Communication and Raising Social Awareness, Industrialization and Market Viability, Innovation as well as Sustainability. During the competition, the public can visit the buildings in the Solar Village.

The Technical University of Denmark’s FOLD project

Among the 20 prototypes in last year’s contest was the Technical University of Denmark’s FOLD project (Photo 1). With FOLD the 35-strong team pursued an innovative architectural approach which takes its shape from a folded rectangular sheet of paper. Not only can FOLD be constructed in various sizes and variations depending on the specific conditions of the site, the jury was particularly convinced by the innovative energy concept of the building.

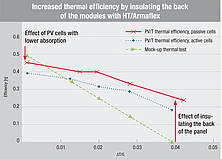

The students developed a completely new PV/T system. The solar system generates both electricity and heat and is much more efficient than traditional photovoltaic or thermal systems. Cooling the solar cells using the integrated water circulation allows a higher electricity yield than can be achieved in purely PV systems (see Figure 1). The water which is heated through cooling the solar cells is used to supply the house with domestic hot water. Once the hot water tank has been fully heated, the solar cells are cooled by a ground heat exchanger.

Optimizing the PV/T system by insulating the modules with HT/ArmaFlex

The solar panels are integrated directly into the roof of the house which underlines the unusual design of the building. The panels consist of a multilayer construction with a front glass which reduces radia-tion from the panels and further optimizes the efficiency (see Figure 2). By insulating the back of the PV/T modules with HT/ArmaFlex it is possible to control the temperature of the solar cells precisely (Photo 2).

HT/ArmaFlex is a highly flexible EPDM-based insulation material. The lightweight material is resistant to UV-rays and high temperatures (up to +150 °C) and is suitable for outdoor applications. HT/ArmaFlex has a low thermal conductivity and therefore reliably reduces energy losses from insu-lated installations. As a closed-cell insulation material HT/ArmaFlex also has an ‘integrated vapour barrier’ and is protected against moisture ingress, thus optimizing the long-term service life of the insulated system.

Project manager Pavel Ševela used 25 mm-thick ArmaFlex sheets which were fully glued to the back of the panels. Figure 3 shows the effect of the insulation. By insulating the modules with HT/ArmaFlex it was possible to reduce the heat loss coefficient considerably compared to the mock-up panel, or in other words: the range of working conditions was greatly increased.

Pre-insulated solar thermal pipes

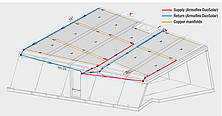

The water supply to the solar panels was ensured with ArmaFlex DuoSolar, the pre-insulated twin-pipes for solar systems made by Armacell (Photo 3). Pavel Ševela used pipes with an inner diameter of DN25. The supply and return lines consist of flexible corrugated stainless steel pipes which are insulated with HT/ArmaFlex. The high-temperature insulation material prevents unnecessary energy losses and moisture ingress. A robust foil covering protects the pipes against mechanical damage and UV rays. The high flexibility of ArmaFlex DuoSolar VA allows easy installation even in difficult situations (Photo 4). The pipes run under the PV/T modules and roof cladding and in the cavity of the outer wall cladding. The corrugated stainless steel pipes did not kink even on sharp bends. Thanks to the patented join-split technology the pipes could be separated and rejoined easily when the house was transported and re-erected in Spain.

Simple and reliable installation with the quick-fitting couplings from Armacell

Armacell’s proven quick-fitting couplings were used to assemble ArmaFlex DuoSolar VA. This allowed the pre-insulated corrugated stainless steel pipes to be connected to the system components of the PV/T system quickly, simply and reliably. The connection is made by simply tightening a nut. Using the quick-fitting couplings allows considerable cost savings in the installation process and eliminates the time-consuming flanging of connections. The quick-fitting couplings ensure that the corrugated stainless steel pipes are safeguarded against leakages in the long term. The connection remains tight even after repeated assembly and dismantling. The couplings do not cause a fall in pressure in the pipes.

Pavel Ševela was so thrilled with the fast and easy assembly of the fittings that he also used them to connect the copper pipes which run under the PV/T module and cool the solar panels. To connect the copper pipes between the panels the pre-insulated flexible ArmaFlex DuoSolar pipes were used which were also installed using quick-fit couplings.

Solar System Integration Award

The PV/T panels not only supply the house with hot water and electricity, they also feed the energy surplus into the electricity grid. With a total panel area of 70 m² FOLD would generate an average of 12 MW/h of electricity annually when erected in Spain. The ambitious project received the Solar System Integration Award at the Solar Decathlon in Madrid as best competition entry in this category