By Dipl.-Ing. Georgios Eleftheriadis, Armacell Manager Technical Marketing Europe

Münster, 22 May 2012 – From August 2012, only technical insulation products which comply with the European product standards and bear the CE mark may be sold in Europe. A mandatory framework will then apply for the key product features of technical insulation materials – such as thermal conductivity, resistance to water vapour transmission, fire behaviour, tolerances etc. The transparency achieved will allow specifiers, distributors and installers to make a quick and direct comparison between the products on offer. The product designation code provides information on these key product properties. Furthermore, the CE mark provides installers with benefits in terms of product liability. In this article the significance which the European product standards for technical insulation materials have for the participants in the sector is explained and critically discussed. At the same time, a description is given of the route which manufacturers of technical insulation materials must take in order to achieve CE marking for their products. The European fire classification for technical insulation materials is presented and an outlook on the further development of the industry is given.

The road to European product standards for technical insulation materials

Looking back at the time it has taken to draw up and adopt the European product standards for technical insulation materials, the saying ‘good things come to those who wait’ seems fitting. The entire process spanned a period of over 20 years, so many of the original members of the technical committees involved are likely to witness the introduction of this series of standards during their retirement. The European product standards for insulation materials for building equipment and industrial installations were passed by the national standard organizations in the CEN (Comité Européen de Normalisation) in the middle of 2009 and published in the Official Journal of the European Union in June 2010 [1]. Once the transition period has expired, it will only be permitted to sell technical insulation products in the EU countries which comply with the European product standards (and thus with the Construction Products Directive or Construction Products Regulation) and bear the CE mark. The first technical insulation materials with the CE mark – such as the ArmaFlex range made by Armacell (see Photo 1) – have been available since the beginning of 2012. The European product standards for the technical insulation materials were drawn up in the committees of CEN TC 88 / WG 10 and are therefore be referred to as ‘WG 10 product standards’ in the following (see Figure 1). The passing of these standards means that, for the first time, the technical insulation sector now has definitions and classifications for its products which are accepted throughout Europe – and thus an unambiguous nomenclature.In January 2010, the European Commission (Directorate-General Enterprise and Industry) defined the scheduling for the introduction of the WG 10 product standards in ‘Construct 09/873’ [2]. After the publication of the product standards in the Official Journal of the European Union in June 2010, the coexistence period began in August. During this time national standards and provisions which contradict the European product standards may still be used. This period ends in August 2012. The longer coexistence period (usually 12, in this case 24 months) is because it was expected that the accredited testing institutes would very probably be overburdened by the expected number of testing requests for CE marking.

As a package of standards the WG 10 standards are relatively standardized and can therefore be seen as being ‘harmonized’ with each other (see Figure 2). Everyday practice will now show whether the WG 10 product standards and their provisions are ‘serviceable’. Corrections and amendments will be carried out according to the defined CEN procedure after 4 years, but at the latest after 5 years in the course of the standards review.

Prerequisites for attaining the CE mark

The CE mark is an expression and visible indication of the product’s compliance with the requirements of the relevant European directive, i.e. in our case with the Construction Products Directive. The ‘essential requirements’ defined in the Construction Products Directive are substantiated in the product standards.

The assessment of a product’s conformity with the appropriate directive (or directives, when several must be complied with) is the prerequisite for the legally binding declaration of conformity (with use of the CE mark, see Figure 3). Conformity to the directives exists if the essential requirements defined there are fulfilled. The manufacturer is obliged to carry out an assessment of conformity. With resolution 93/465/EEC [4] of the European Council in 1993, a fundamental overall concept for assessing conformity was updated and completed. The guidelines of this concept are:

a) the modular assessment concept

b) the criteria for the application of the procedure

c) the naming of the notified bodies.

This core resolution for assessing conformity also standardizes the rules for applying and using the CE mark and underlines the fact that the assessment of conformity is also carried out with regard to safety, health protection and consumer protection.

In order to attain the CE mark the requirements of the relevant harmonized product standards must be fulfilled. Specifically, this means for the WG 10 standards that:

a) an initial type test (ITT) must be carried out. This follows the specifications of EN 13172 [5] and the relevant product standard (Section ZA.2).

b) factory production control (FPC) must be established. This is specified in Annex A of the WG 10 standards.

The product properties for which an initial type test must be carried out are to be found (depending on the applicable conformity system) in Table ZA.3 or ZA.4 of the product standards or in Annex E of EN 13172.

They are:

- thermal resistance / thermal conductivity and density;

- release of hazardous substances (currently not relevant as there is no testing procedure);

- release of corrosive substances;

- compression stress / compression strength (for applications under load);

- water absorption (including resistance to water vapour transmission) and

- fire behaviour (for applications which are subject to provisions for fire behaviour, except in the case of System 4).

Under DIN EN 13172 [5], three assessment systems (System 1, 3 and 4) are available for insulation materials which are to bear the confirmation of conformity (CE mark). Depending on the fire behaviour of the products, these assessment systems may be combined in order to confirm conformity.

For insulation materials whose fire characteristics can vary in the production process, the initial type tests are to be carried out by an approved or notified body.

Factory production control is carried out for the properties which under the product standards are relevant for all applications (Section 4.2 of the relevant WG 10 standard) and for selective properties in Section 4.3 (for particular applications). Depending on the required properties (i.e. the intended use of an insulation material), the manufacturer is faced with a considerable amount of testing and organization.

The CE mark indicates that the product complies with the relevant national technical standards (which implement the harmonized technical standards), the European technical approvals or a national technical specification in accordance with Art. 4 (3) CPD and that the system of certifying conformity, related to the product, was applied in accordance with the decision of the European Council (or the body of standards derived from it).

The CE mark is to be affixed on the product in such a way that it is clearly visible, legible and permanent. If this is not possible for certain products – as is the case for technical insulation materials - it may also be affixed on the packaging or (if available) on the accompanying document. The product designation code provides information on key product properties. In the case of technical insulation materials, for example, these are the upper and lower use limits, the fire classification and the resistance to water vapour transmission (see Photo 2).

The manufacturer or his authorized legal representative within the European economic area is responsible for affixing the CE mark. With the CE mark the body named (i.e. the certifying institute), the principle area of application and the ‘harmonized’ (technical) properties are also to be given.

The declaration of conformity should be written in the official language of the member country in which the product is used. Here it is also the manufacturer who is responsible for the correct translation. It goes without saying that depending on the procedure for assessing conformity more or less extensive documentation must be drawn up and kept for at least 10 years under the product liability law.

In the event of doubt or dispute for example, this documentation can serve as an instrument of evidence and must be made available to the appropriate state authorities, for example the public prosecutor’s office. This raises the question, what happens if the CE mark is used without taking into account and conducting the appropriate measures described here? The answer is simple: this would constitute an infringement of the law and a fine of up to 50 000 euros could be imposed (§ 14, German Construction Products Law) [6].

Compliance with the CE directives is mainly monitored by the trade supervisory authority or the building supervisory authority. Above and beyond this, the European Union also relies on the self-regulation of the market: the eyes of the competitor are considered to be an effective means of supervision!

Once an insulation product has undergone successfully all the measures for CE marking described, the sale of this product within the European Union must not be hindered. In this sense the CE mark also serves as a ‘passport for goods’ and is not to be seen as a seal of quality in the stricter sense. It is therefore expressly pointed out that the CE mark should not serve advertising purposes – because in future all products for which directives apply under the new approach will bear the CE mark.

European fire classification of technical insulation materials

A significant reform brought about by the CE certification of technical insulation materials is that the previous national fire classifications have been replaced by standardized European fire classes In the past, the classification of the fire behaviour reflected the national safety concept of the country in question. Although similarities in the concepts were discernable, the national ‘fire philosophies’ and test methods were very different in certain aspects. It was not, therefore, possible to make a direct comparison between the different building material classifications of the various countries. With the introduction of the European fire classes, the ‘Euroclasses’, these different ‘fire philosophies’ and test methods were harmonized.

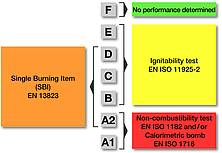

The classification of the fire behaviour into Euroclasses is to be carried out in accordance with EN 13501-1 [14]. The limit values given in Table 1 of the EN 13501-1 are to be used for flat elastomeric products (FEF); the values in Table 3 for linear elastomeric products. The Euroclasses and the associated test methods are presented in Figure 4.

Consequently, the SBI Test method (Single Burning Item; (EN 13823, [8]) and what is known as the Ignitability Test (EN ISO 11925-2, [9]) are used for combustible technical insulation materials. In the SBI Test, the potential contribution of a construction product to a developing fire is assessed in a fire scenario which simulates a single burning item in a room corner close to this construction product (see Photo 3).

The Ignitability Test, on the other hand, assesses the ignitability of a construction product by exposing it to a small flame.

The new classification uses the seven fire classes A to F which are already valid for other construction products. For pipe insulation a subscripted ‘L’ (for ‘linear products’) is added. Another new feature is the information on smoke development and burning droplets, which will be marked with ‘s’ and ‘d’ respectively.

The limit values which are relevant for the fire behaviour of linear products are considerably higher than the classification values for flat products, i.e. easier to achieve. This is due to the chosen reference scenario which was carried out within a scientific project under the auspices of the Swedish testing institute SP in 2002 [10]. In this project the Room/Corner Test was used as the reference scenario for assessing linear insulation materials in the SBI. Apart from verifying that there is an excellent correlation between the test results provided by the two methods, a realistic number and arrangement of the pipes to be insulated was chosen, which led to an equally realistic determination of the classification limits.

Elastomeric technical insulation products, the FEF products, typically achieve fire classifications of D-s3, d0 to B/BL-s3, d0 – depending on the type of insulation material. With ArmaFlex Ultima Armacell presented at the ISO ’12, the key European trade fair for insulation technology in Cologne (Germany), the first elastomeric insulation material to achieve fire class B-s1, d0. The new insulation material has an extremely low smoke density, thus making an important contribution to the overall level of fire safety in buildings. ArmaFlex Ultima is patent pending and will be launched on several European markets in autumn. (see photo 4)

In Germany, the transposition of national to European fire classes was carried out by the Deutsches Institut für Bautechnik (German Institute for Structural Engineering) as early as 2002 [11]. The German transposition observes the definitions of the Construction Product Directive and Guidance Paper E (‘Levels and classes in the Construction Product Directive’) [12] and is therefore realistic and also ‘in line with the market’ in the best sense of the term. The essential statement of Guidance Paper E (Section 4.11) is basically: a product which has been well-known and successfully used in a specific market for years must not in the course of a specific member state’s adoption of European directives or standards be excluded from this market.

In other European countries attempts have been made to take the opportunity presented by the transposition of the Euroclasses into national law to introduce changes to the national classification system (supposedly increasing safety) by the back door. In some cases this means that products which have been used successfully without any problems for decades in the countries in question under the previous classification could be excluded from the market in future. This is contradictory to the ‘non-discrimination rule’ given in Guidance Paper E of the Construction Product Directive and would thwart the idea behind CE marking (opening up markets, liberalization and removing obstacles to trade).

Significance of the CE mark for the market participants

The European product standards and the CE mark for technical insulation materials offer all market participants (manufacturers, distributors, specialist installers, specifiers etc.) improved opportunities for developing the market, driving it forward and thus achieving their respective goals.Although there are some grounds for criticism, the harmonization of the test methods and classifications has essentially turned out well and represents a big step forward. This is not, of course, the end of the development. In the course of future reviews of the harmonized standards some details will have to be adapted or even changed once further experience has been made – but the step towards European harmonization in the technical field appears to have been successful. However, there is consensus among the manufacturers of technical insulation materials that, for example, the European fire classes should not exist alongside national fire classes. They are also convinced that national requirements should not be established in addition to the defined system of EU fire classification – something which is already common practice in some EU countries. Such practices would thwart the objective of dismantling trade barriers between the EU member states. The declaration of conformity with the CE mark within the framework of the Construction Products Directive and using the harmonized product standards which have now been accepted (including the clearly defined requirements for attaining European fire classes for technical insulation materials) should be the ideal way to comply with national regulations too and thus be entitled to use and not only sell the product in question. In addition the relationship between CE marking and other ‘voluntary’ marking of products (Keymark / DIN Certco etc) must be clarified.

If the European Commission is to be believed, the introduction of the CE mark should bring more certainty to the field of technical insulation. At least all participants in the market will have a better basis on which to make their technical, commercial or even legal decisions.

Some may view the fact that manufacturers of technical insulation materials must comply with the requirements and definitions of the product standards as a disadvantage, but it also offers enormous opportunities. For example, manufacturers will for the first time have the chance to develop a product for the whole European market which can be sold - and often also used - across all national borders.

Compliance with the harmonized product standards is the prerequisite for free trade of technical insulation materials in Europe. In the future, distributors will be able to organize their businesses more effectively without being hindered by national regulations. Insulators and specifiers will benefit from being able to offer and apply their expertise throughout Europe much more easily. Invitations to tender will no longer have to be tied to national borders. Initially, this all sounds very positive. But although harmonized product standards define product properties of the insulation materials and help to classify these technical properties properly, they do not provide information about the minimum values for these properties – and this is also not the case for specific applications. Although that was indeed the intention – only to define technical properties and not to define minimum values for specific applications – it is difficult to communicate and could be interpreted by uninitiated users as being a ‘weak point in the system’.

The different national provisions, which define levels of safety or energy-saving requirements, for example, will continue to exist. Consequently, manufacturers will still be obliged to take national peculiarities into account in their products versions, at least to some extent.

In general, however, professional users of technical insulation materials are provided with a higher level of certainty when using the products.

For the first time, a mandatory framework has been defined for product properties (such as thermal conductivity, resistance to water vapour transmission, fire behaviour, tolerances, etc.). The transparency created allows installers to make a quick and direct comparison between the products on offer. The same rules now apply for everyone. This also leads to a great benefit as far as product liability is concerned: when damage occurred in the past, it was often difficult for courts to check whether products complied with the claimed properties. The European standards will make this easier, giving the installing companies better chances of winning their case. The same is true for insurance claims.

Outlook: Quality assurance for technical insulation materials

In order to achieve proper implementation of the European standards for ‘Thermal insulation for building equipment and industrial installations’ and attain the CE mark, leading manufacturers of technical insulation materials made of foamed plastics set up the FEF/PEF working group under the umbrella of the European quality assurance association for rigid foam (GSH - Güteschutzgemeinschaft Hartschaum) in May 2011. Further manufacturers have since joined the working group. Last year, the member companies approved quality requirements for elastomeric and polyethylene insulation materials and introduced the RAL FEF/PEF Quality Mark. The awarding of the RAL mark is tied to strict monitoring under the quality and test regulations. With this voluntary agreement to monitor its products continuously and independently according to the statutes of the RAL, the manufacturers underline their commitment to assure the quality of their products.

In January 2012, leading manufacturers of technical insulation materials then initiated the foundation of the European FEF and PEF Interest Group (CEFEP). The interest group represents the industry on important European and national committees and would like to provide users with reliable guidance when selecting and installing products. It creates standards which exceed the minimum requirements of the European norms and prevents increased com-plexity in the single market by largely avoiding voluntary national approvals and test cer-tificates. This is intended to create greater transparency and reliability for all involved in this line of business. Taking into account the provisions of the CE mark rules, the CEFEP is striving to achieve a standardized depiction of the product designation codes. At the same time, each of the members of the interest group maintains a distinct portfolio of products and its own marketing strategies, strictly observing competition law.

References:

[1] “General Situation of European Standardisation (latest version: Nov. 2009)”

Taken from: www.cen.eu/CEN/sectors/sectors/construction/Pages/default.aspx

[2] European Commission – Enterprise and Industry Directorate-General, Construct 09/873, 26.01.2010

[3] Resolution of 7 May 1985 on a new approach to technical harmonisation and standardisation (Official Journal C 136 of 4.6.1985).

[4] Decision of the Council 93/465/EWG of 22.07.1993, on the modules for the various phases of the procedure for assessing conformity and the rules for affixing and using the CE mark of conformity to be used in the technical harmonization directives. (Official Journal L 220 of 30.08.1993, pp. 23-39)

[5] BS EN 13172:2012, Thermal insulation products. Evaluation of conformity, BSI, London

[6] Bauproduktengesetz (German Construction Products Law) of 28.04.1998, BGBI. I, p. 812

[7] EN 13501-1: 2007 ‘Fire classification of construction products and building elements. Part 1 Classification using test data from reaction to fire tests’

[8] EN 13823, EN 13823, Reaction to fire tests for building products - Building products ex-cluding flooring exposed to thermal attack from a single burning item.

[9] ISO 11925-2, Reaction to fire tests for building products - Part 2: Ignitability when subjected to direct impingement of flame (ISO 11925-2:2002)

[10] "Development of a common European system for fire testing of pipe insulation based on EN 13823 (SBI) and ISO 9705 (Room/Corner Test)" published as SP Report 2002:21

[11] DiBt – Mitteilungen Sonderheft 26, Anlage 0.2, 1/2002

[12] Guidance papers A to K, EUROPEAN COMMISSION ENTERPRISE DIRECTORATE-GENERAL, Construct 02/558, Brussels, 29 July 2002

[13] Dipl.-Ing. (FH) Wolfgang Albrecht, FIW München, DIN 13162 - DIN 13171: Einführung der neuen CEN-Dämmstoffnormen (Introduction of the new CEN standards for insulation materials), in Isoliertechnik, Vol. 28. Issue 1/2002, pp. 69-71.

[14] Dipl.-Ing. Ulrich Rohr, Armacell GmbH, Europäische Brandprüfungen (European fire tests), in Isoliertechnik, Vol. 25, Issue 4/99, pp. 18-35.

[15] Construction Products Directive (89/106/EEC); ABI. EG No. L 40, p. 12.

Author biography:

Georgios Eleftheriadis has been employed by Armacell (formerly Armstrong Insulation Products), Münster since 1989. He has held various technical positions and was also Manager in charge of Public Relations. He is currently working in the European Armacell Marketing group as Manager Technical Marketing Europe. He is the Convenor of CEN/TC 88, WG10 TG PEF, chairman of the European FEF and PEF Interest Group (CEFEP) and works on various other European and national committees.