SAFE, RELIABLE AND ENERGY EFFICIENT INSULATION

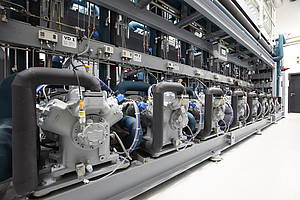

When safety, energy efficiency and a healthy indoor climate are the top priorities in construction projects, ArmaFlex Ultima is the obvious choice for equipment insulation. At its new company headquarters in Kernen (Germany), the specialist wholesaler Fischer

Kälte-Klima relies on the new safety standard in insulation technology. ArmaFlex Ultima exhibits 10 times less smoke in a fire than a standard elastomeric product, making it the safest solution for cooling equipment.

INCREASED FIRE SAFETY WITH ARMAFLEX ULTIMA

As safety is the top priority in the new Kälte-Fischer building, a fire protection expert was consulted during the planning phase, who recommended the use of the low-smoke elastomeric insulation

material ArmaFlex Ultima. The entire NH3 heat pump, including the hydraulic section, was insulated with ArmaFlex Ultima by Fischer’s Systems Engineering division. The insulation firm Brandschutz-Isolierungen Zschopau from Gornau was commissioned to insulate the building services pipes.

«In a fire, low smoke density allows occupants more time to leave the building and rescue teams unhindered access for evacuation.»

Matthias Klauser, responsible for planning the building services.

ARMAFLEX ULTIMA - INSTALL IT. TRUST IT.

Based on the patented ArmaPrene™ technology, ArmaFlex Ultima is the first flexible technical insulation material in the world with fire class BL-s1,d0 and exhibits 10 times less smoke in a fire than a standard elastomeric foam. Thanks to its low thermal conductivity and high resistance to water vapour diffusion, closed-cell ArmaFlex Ultima ensures reliable condensation control and high energy savings in the long-term.