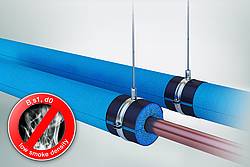

Münster, 5 April 2013. – Armacell now also offers its tried-and-tested pipe support for air-conditioning and refrigeration applications in the new ArmaFlex Ultima quality. ArmaFix Ultima provides maximum reliability: the pipe support thermally isolates the pipe from its bracket, preventing thermal bridges occurring. The blue elastomeric foam achieves fire class BL-s1, d0 and thus has extremely low smoke density in a fire. The products in the ArmaFlex Ultima range make an important contribution to the level of fire safety in buildings.

Strengthening the weakest link in the chain

Pipe brackets represent a potential weak point in insulation work. If the pipe is not thermally isolated from the pipe bracket, thermal bridges occur and condensation can form. On the one hand, this leads to increased energy losses and, on the other hand, the risk of corrosion and the danger of expensive secondary damage rise. To prevent thermal bridges, direct contact between the pipe and its bracket should be avoided. ArmaFix Ultima thermally isolates the pipe and bracket from each other and installed together with ArmaFlex Ultima tubes or sheets it guarantees an insulation system that provides long-term reliability in cold applications. The pipe support consists of compression-proof PUR/PIR segments, which are embedded in the closed-cell insulation material. On the outer surface they are glued to coated aluminium shells which distribute the load and also act as an additional vapour barrier.

Low smoke density decisive for people’s safety in a fire

In the event of a fire it is vital that people trapped find escape routes quickly – which is only possible with minimal smoke development. Therefore, when assessing the fire behaviour of building products, the new European fire classification not only tests the flammability, but also the smoke density and the production of burning droplets. The products in the new ArmaFlex Ultima range are the first flexible insulation materials to achieve fire class BL-s1, d0 (B-s2, d0 for insulation sheets) in the European fire test. In comparison to standard elastomeric products, ArmaFlex Ultima exhibits 10 times lower smoke development and makes an important contribution to the people’s safety in buildings.

Keeping an eye on the overall costs of cold pipe supports

Comparative calculations carried out by Armacell have shown that the ArmaFix Ultima pipe support not only provides maximum reliability, but can also be installed more easily, neatly and quickly than common clamps and pipe supports. When using standard clamps it is necessary to insulate the pipe up to the clamp, glue the ends of the insulation material to the pipe and then apply ArmaFlex to the supporting device. In contrast, ArmaFix is simply snapped around the pipe by the plumber and fastened by means of the self-adhesive closure without any need for additional wet bonding. The insulator then simply glues the butt ends of the pipe support to the tube material.

Special adhesives for the ArmaFlex Ultima range

ArmaFlex Ultima and other insulation materials based on Armaprene® synthetic rubber are glued using adhesives which have been specially developed for these products:

- ArmaFlex Ultima RS850 Adhesive: thixotropic, gel-like, high-performance adhesive for clean, non-drip application

- ArmaFlex Ultima SF990 Adhesive: the first solvent- and emission-free adhesive, which was developed for the rising demands of sustainable building

- ArmaFlex Ultima 700 Adhesive: reliable special adhesive for a wide temperature range

The choice of adhesive depends on the requirements of the project in question.