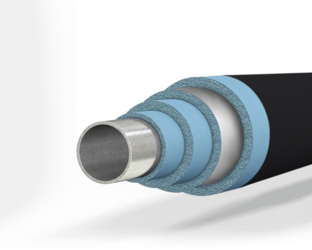

ARMAFLEX® ULTIMA FOR CRYOGENIC APPLICATIONS

In cryogenic applications, where extremely low temperatures present unique challenges, ArmaFlex Ultima is the solution of choice. It optimises energy efficiency, minimises heat loss, and significantly reduces the risk of corrosion under insulation and ice formation. Based on

our patented ArmaPrene® technology,

ArmaFlex Ultima has been rigorously tested and certified, proving its mettle in the demanding cryogenic environments of Air Liquide, a leading global provider of liquefied gases.

INNOVATION AND TESTING: THE FOUNDATION OF SUCCESS

Our collaboration with Air Liquide has set new benchmarks in the insulation of cryogenic systems, achieving remarkable results that underscore the performance, reliability and durability of ArmaFlex Ultima. This partnership showcases our commitment to excellence and positions ArmaFlex Ultima as the go-to insulation solution for industry leaders.

Partnering with Armacell allowed us to achieve a uniform insulation system across all our cryogenic plants, marking a significant step forward in our commitment to operational excellence and sustainability.

Ivan Sanchez Molinero

IM Engineering Head - EIM - Central Europe Cluster Air Liquide

PROVEN PERFORMANCE UNDER EXTREME CONDITIONS

The findings from our joint testing with Air Liquide reveal that all samples of ArmaFlex Ultima exhibited exceptional performance, maintaining robust mechanical properties and low water absorption rates. This performance is pivotal in preventing ice formation on pipes and equipment – a significant risk that can obstruct valves, cause surface corrosion, and potentially damage the system. Compliance with ISO 23766:2022 Method B during testing provided valuable insights into the coefficient of linear thermal expansion, confirming ArmaFlex Ultima’s capacity to withstand and adapt to the intense thermal contraction associated with cryogenic temperatures.