Münster, 14 January 2014 – With the introduction of the CE marking for technical insulation materials in August 2012, national fire classifications – such as the German fire classes in accordance with DIN 4102 – were replaced by harmonized European fire classes. The European system uses the seven fire classes A to F familiar from other building products. A completely new aspect for technical insulation materials is that smoke development (‘s’) and burning droplets (‘d’) are also included. Whereas in the past technical insulation materials were primarily assessed according to their flame resistance, the smoke classes now allow a more realistic evaluation of the fire behaviour of the various products. Legislators in many European countries have recognized that smoke poses a much greater hazard potential than the fire itself and have tightened the requirements regarding the smoke development of construction products in their building regulations. In Sweden, only technical insulation materials that achieve at least fire class BL-s1, d0 may be used in so-called Br1 buildings – these are buildings requiring special fire protection such as hotels or hospitals. With the fire classification BL-s1, d0, Armacell’s ArmaFlex Ultima has set a new safety standard in technical insulation. The highly flexible, closed-cell insulation material has extremely low smoke density and thus makes an important contribution to overall level of fire safety in buildings.

Every year 6 000 to 10 000 people die as a result of fires in Europe. But only a few of these are killed by the flames; the majority – 95 % of fire fatalities! – die as a consequence of smoke inhalation. In the event of a fire it is vital that those trapped find escape routes quickly – which is only possible with minimal smoke development. The new European fire classification takes this fact into account and when assessing the fire behaviour of building products not only tests the flammability, but also the smoke density and the production of burning droplets.

Conflict of objectives: fire protection treatment and smoke development

Like all organic products flexible elastomeric insulation materials are combustible. In order to ensure that the insulation material is optimally protected against fire, various flame retardants are added. Flame retardants are additives which reduce the ignitability and burning rate through physical and/or chemical action, but do not prevent the materials themselves being combustible. Up to now, organic-based technical insulation materials could only achieve the best construction materials classification for combustible building products with the aid of halogenated systems, because other flame retardants are only effective at relatively low temperatures. Brominated flame retardants inhibit combustion very effectively, but due to their mode of action and their effect they lead to quite high smoke development especially in the gas phase. For this reason, standard elastomeric products achieve a good fire classification in the European SBI test – the majority of premium products are classified as ‘B’, i.e. of low flammability – but they tend to have higher smoke development and so far have at best been classified as ‘s3’. Elastomeric insulation materials with lower smoke development (‘s2’ or even ‘s1’), on the other hand, only achieve fire class E or at best D. This means in practice that up to now the user had to choose between an insulation material with a good fire classification or with low smoke development.

Elastomeric insulation materials with low smoke development

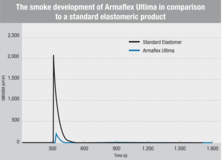

By taking a completely new approach Armacell has now been able to resolve this conflict of objectives. Due to the development of completely new, intrinsically flame-resistant polymers and using ablative protective additives it is no longer necessary to add any brominated flame retardants. The completely new foam ‘ArmaFlex Ultima’ combines for the first time extremely high flame resistance with minimal smoke development. The blue elastomeric foam is the first flexible insulation material to achieve fire class BL-s1, d0 (tubes) or B-s2, d0 (sheets). Compared to a standard elastomeric product, ArmaFlex Ultima exhibits 10 times less smoke development.

Legislators in many European countries have recognized that smoke poses a much higher hazard potential than the fire itself and have tightened the requirements regarding the smoke development of building products in their building regulations.

Tip: The superior fire behaviour of ArmaFlex Ultima is also demonstrated in a video which can be found at www.armacell.de/ArmaFlexUltima